A wind turbine consists of five major components and many minor parts. The main components are the foundation, the tower, the rotor and hub (including the three blades), the nacelle and the generator. The installation of all these components requires the use of specific wind turbine specific mounting equipment.

1、Foundation of wind turbine

For onshore wind turbines their foundation is located on the ground; it is invisible because it is covered with dirt. It is a large and heavy concrete block that must support the entire wind turbine and the forces acting on the turbine.

In offshore turbines, the foundation is also invisible underwater. For offshore turbines far from land, the foundation is floating but has enough mass to support and sustain the weight of the turbine and the forces acting on it.

2.Wind Turbine Towers

The tower of most modern wind turbines is made of round steel tubes. A rule of thumb for a wind turbine tower is that it is the same height as the diameter of the circle formed by the blades of the turbine it carries as they rotate. In general, the higher the turbine, the easier it is to capture the high speed wind. This is because the farther we are from the ground, the higher the wind will be (wind speed varies from height to height).

3.Rotor and hub of a wind turbine

The rotor is the rotating part of a turbine; it consists of three blades and a central part to which the blades are attached, the hub.Although three blades are the most common, turbines do not necessarily have to have all three blades. However, three-blade rotors offer advantages such as optimal efficiency. The blades are not strong; they are hollow and made of a composite material that is both lightweight and strong.

The trend is to make them bigger (for more power), lighter and stronger. For aerodynamics, the blades are shaped like wings (like the wings of an airplane). In addition, they are not flat and will be designed with a twist between their root and tip. The blades can rotate up to 90° about their own axis, a movement called pitch. The function of the hub is to hold the blades and allow them to rotate relative to the rest of the turbine body.

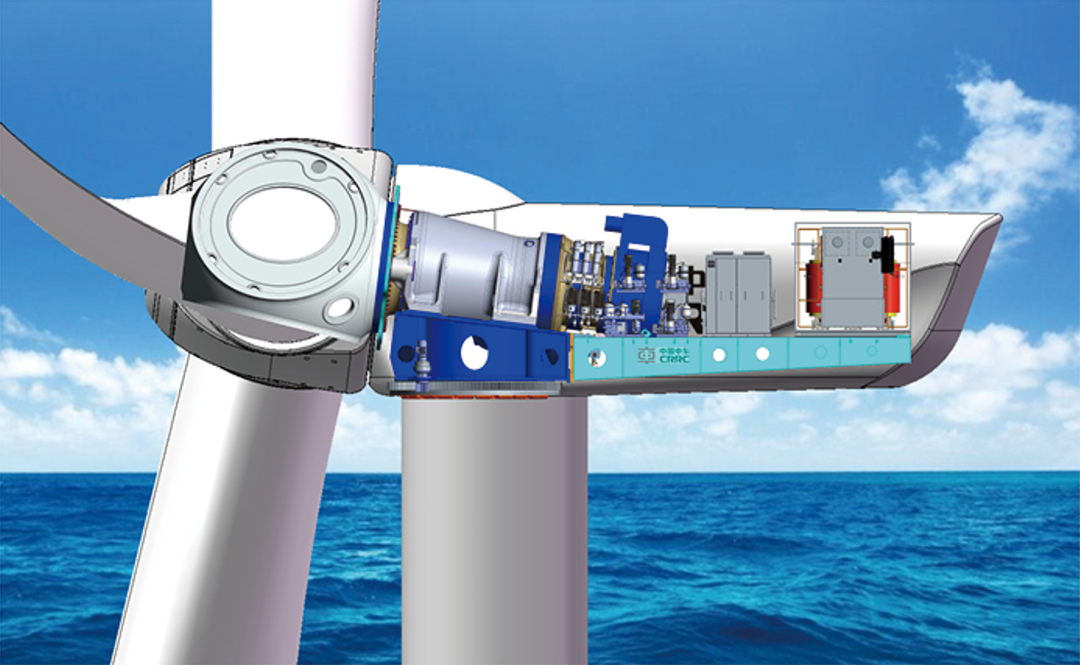

4.Wind turbine nacelle

The nacelle houses all the components that need to be mounted on top in the wind turbine.The nacelle of a wind turbine is a complex electromechanical system with a considerable number of components that work precisely and properly. The important wind turbine components are the generator and the main shaft, which transmits the energy from the collected wind to the generator through the gearbox.

The gearbox is another important component of the wind turbine.Since the wind turbine must work downwind and needs to adjust its direction to the wind, its rotor must be able to rotate relative to the tower. This rotational motion is called yaw.

5.Wind turbine generator

A generator is a component that converts the mechanical energy of the rotor (obtained from the wind) into electrical energy. Generators have the same structure as electric motors.

Although there are various types of wind turbines, they can be summarized into two categories

(1) Horizontal axis wind turbines, where the rotation axis of the wind turbine is parallel to the wind direction

(2) Vertical axis wind turbines, where the rotational axis of the wind turbine is perpendicular to the ground or to the direction of the airflow.

Horizontal axis wind turbine

Horizontal axis wind turbine is divided into two types: lift type and resistance type.

Lifting type wind turbines rotate fast, while resistance type rotates slowly. For wind power generation, most of the horizontal axis wind turbines are of the lift type. Most of the horizontal axis wind turbines have a counter wind device, which can rotate with the change of wind direction. For small wind turbines, this counter wind device uses a tail rudder, while for large wind turbines, a wind sensing element is used as well as a drive mechanism consisting of servo motors.

Wind turbines with the wind wheel in front of the tower are called upwind wind turbines, while those with the wind wheel behind the tower become downwind turbines. There are many types of horizontal axis wind turbines, some have reversing blade wind turbines, some install multiple wind turbines on one tower in order to reduce the cost of the tower under the condition of certain output power, and some horizontal axis wind turbines produce vortex around the wind turbine to concentrate the airflow and increase the airflow speed.

Vertical axis wind turbines

Vertical axis wind turbines do not need to oppose the wind when the wind direction changes, which is a major advantage over horizontal axis wind turbines in this respect. It not only makes the structural design simpler, but also reduces the gyroscopic force when the wind wheel opposes the wind.

Double-Fed Induction Generator

With the development of power electronics, the Double-Fed Induction Generator (DIG) is increasingly used in wind power generation. This technology does not depend too much on the capacity of the battery, but starts from the excitation system and controls the excitation current appropriately to achieve a constant frequency power output. Doubly-fed induction generators are similar in structure to asynchronous generators, but in excitation they use AC excitation.

We know that a pulsating magnetic potential can be decomposed into two rotating potentials in opposite directions, and the proper arrangement of the three-phase winding can eliminate the effect of one of the potentials, thus obtaining a rotating potential in space, which is equivalent to the rotor of a synchronous generator with DC excitation. The advantage of the doubly-fed generator is that the frequency of the AC excitation is adjustable, which means that the frequency of the rotating magnetic potential is adjustable.

This means that the frequency of the rotating magnetic potential is adjustable, so that the frequency of the excitation current can be adjusted to meet the purpose of constant frequency power output when the speed of the prime mover varies. Since the capacity of power electronics is increasing, the excitation system of doubly-fed generator sets is becoming more and more adjustable, which makes it possible to increase the individual capacity of doubly-fed machines.

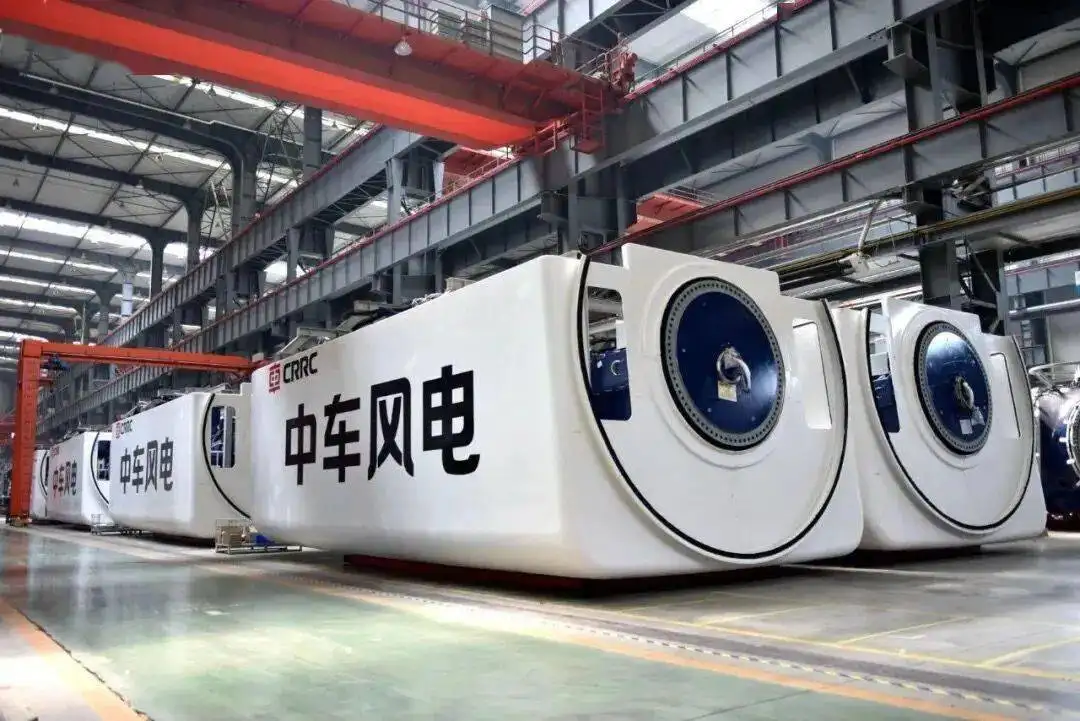

О CRRC

In 2021, CRRC ranks first in China in terms of sales of wind turbine generators, second in terms of sales of blades, third in terms of sales of towers, and fourth in terms of new onshore installations of wind turbines. Now the cumulative installed capacity is 13GW, generating approximately 32.5 billion kWh of electricity per year, which is equivalent to saving 10.82 million tons of standard coal, reducing 29.14 million tons of CO2 emissions and planting 1.6 billion trees.

As of June 2022, CRRC has provided more than 9,300 wind turbines, 16,000 sets of wind blades, 65,000 sets of wind generators, 12,500 sets of wind towers, 5,000 sets of wind converters, 1,800 sets of wind gearboxes, and 10,000 sets of wind supercapacitor modules and 500 sets of pitch systems for wind power generation enterprises.

CRRC has become an important force in the domestic wind power industry, forming a whole industry chain of wind power from core components such as generators, blades, towers, gearboxes, converters, supercapacitors and pitch systems, to complete machine manufacturing and intelligent operation and maintenance.

At the same time, CRRC has also built up the capability of wind power project whole life cycle system solution from resource development, complete machine manufacturing, project EPC, intelligent operation and maintenance.

Генераторы

CRRC wind turbine products cover a full range of technical lines such as cage, double-fed, direct-drive permanent magnet, medium-speed permanent magnet, high-speed permanent magnet, etc. The power level covers 600KW-13MW, with the ability to provide research and development and supporting capabilities for various types of wind turbines.

We have provided more than 65,000 sets of wind turbines for the domestic wind power market, which have been successfully applied to domestic wind farms in the north, south and east and foreign wind farms in the United States, Southeast Asia and Europe, with the first market share in China.

Лезвие

The installed blade range covers 29 provinces/municipalities/regions in China, and 14 countries in Northern Europe, South Asia and America, with a cumulative installed capacity of over 30GW, and the market share ranks second in China and among the top three in the world.

Tower

CRRC entered the wind power equipment tower manufacturing field in 2006, and its business covers the production and manufacturing of wind power towers, large steel structures, pressure vessels, large energy storage tanks, new energy equipment and other products. After more than ten years of development, it has established more than 30 production bases nationwide and has an independent tower operation and maintenance system to provide services for domestic tower market operation and maintenance.

The installed capacity is more than 30,000MW and the number of installed units is more than 12,500 sets, ranking top three in the domestic onshore tower market. And we can provide customized services to paint different themes of wind turbine towers. From the spraying process, stencil production and other aspects of strict control, quality inspection personnel on-site throughout the follow-up, in order to achieve the best visual effect, spraying and then carefully repair the pattern to ensure the final quality of the product.

Основная система управления и система шага

CRRC gives full play to its technical accumulation and innovation ability in the field of electrical system of railway vehicles, and successfully transplants the intelligent and efficient technical characteristics and superior quality of electrical products of high-speed trains to the wind power business, forming a spectrum of wind power main control system products and whole life cycle pitch system.

Complete wind turbine

CRRC entered the field of wind power equipment complete machine manufacturing in 2006, and has a product spectrum of onshore and offshore high-power units with the latest technology level. The series products are suitable for complex environments such as high altitude, low wind speed, high temperature, low temperature, sand, humidity, etc. They are characterized by high degree of intelligence and high reliability. At present, the number of installed units exceeds 6,000 units.

Current Status

CRRC onshore wind turbines cover 1.5MW, 2.xMW, 2.5xMW, 3.xMW, 4.xMW, 5.xMW, 6.xMW, 7.xMW, 8.xMW and other power levels, realizing wind power product type spectrum.

CRRC has developed 40-100m level blades, and is promoting the development of blades above 100m, the main products are 146 series blades, 155 series blades, 16X series blades, 17X series blades, 18X series blades, 19X column blades.

CRRC has also introduced the international cutting-edge orbital traction motor technology accumulated for more than 60 years into the whole process of wind turbine development, and has become the leader of wind turbine technology. The self-developed products cover 1.2MW-14MW direct-drive permanent magnet wind turbine, 2MW-16MW semi-direct-drive permanent magnet wind turbine, 750kw-6MW double-fed asynchronous wind turbine, and wind power transformers such as large-capacity main transformer, medium-sized oil transformer, small oil transformer and distribution transformer.

In terms of wind power tower manufacturing, CRRC can meet the production of 5MW-16MW high-power wind turbine towers, and has the annual production capacity of 600 sets of wind power tower equipment.

Boland Renewable Energy Co.,LTD As an integrated new energy power company, providing you with high quality integrated wind energy , solar energy and energy storage system solutions.Boland is now a subsidiary of CRRC, and is responsible for the overseas expansion of CRRC's wind power & solar power business. We have a relatively complete internal supply chain, service network and excellent product quality and technology.

Boland Обеспечить EPC электростанции, инвестиции и приобретение электростанции.

Пожалуйста, не стесняйтесь обращаться к нам, если вам нужна техническая поддержка. Приветствуем наше сотрудничество!

Моя электронная почта: marketing@boland-hydroturbine.com

Вашингтон: +8613923745989