(I) Composition of hydraulic turbine

1、Water diversion parts

Composition: water-guiding chamber (runner chamber), seat ring.

Role: to small hydraulic loss of water flow uniformly and symmetrically into the water-guiding components, and before entering the guide leaf to form a certain amount of ring.

2、Water-guiding parts

Composition: the water guide mechanism consists of top cover, bottom ring, guide leaf, connecting rod mechanism and receiver.

Role:

(1) is to make the water flow into the runner before the formation of rotation and change the angle of incidence of water flow ;

2)It is used to adjust the flow rate when the output of the unit changes.

(3) normal and accident shutdown, used to cut off the water flow.

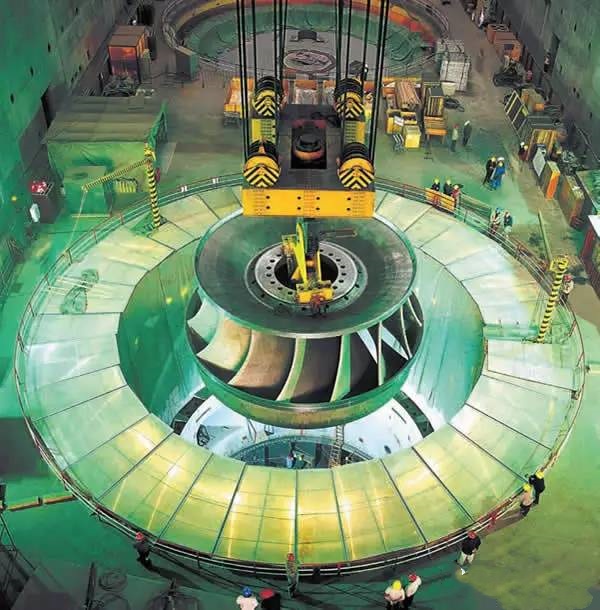

3、Working parts

Composition: rotor and paddle.

Role: directly convert the water flow energy into rotating mechanical energy.

4、Drainage parts

Composition: water discharge cone, tail water pipe.

Role: to guide the water flow into the downstream, the tail water pipe at the same time also form a vacuum after the runner, using the potential energy between the runner exit and the tail water downstream, to restore part of the kinetic energy loss at the exit of the runner, in order to improve the efficiency.

(ii) The turbine is divided into three main parts

Rotating part, fixed part and buried part.

1、Rotating part

The rotating part is the core component of the unit, which is the key to convert water energy into mechanical/electrical energy.

The rotating part and its related components mainly include: rotor, main shaft, main shaft seal, etc.

1) Runner

a) The rotor is the main component for water energy conversion. It converts most of the water energy into rotating mechanical energy of the rotor and transfers it to the generator through the main shaft of the turbine.

b) The rotor of the turbine converts the water energy into mechanical energy.

2) Main shaft

The main shaft is to bear the weight of the rotating part of the hydraulic turbine and the tensile force generated by the axial water thrust, and at the same time to transmit the torque generated by the runner.

3) Main shaft seal

The main shaft seal is one of the key components of the hydraulic turbine. During the operation of the hydraulic turbine, the safe and reliable operation of the main shaft seal is directly related to the safe operation of the hydraulic turbine.

The role of sliding frame seal is to effectively block the water in the tailwater pipe from overflowing the gap between the main shaft and the top cover, to prevent the hydraulic turbine guide bearing and the top cover from being flooded, and to maintain the normal operation of the bearings and the unit.

4) Service seal

The service seal is a kind of seal, also called the air envelope, which is put into use when the unit is overhauled, inspected or due to the damage of the main shaft seal;

Inspection seal: when put into the compressed air into the air enclosure, so that the protruding parts of the air enclosure to hold tight to the water-guided rotating oil basin with which the machining surface or the large shaft flange, cut off the tail water to prevent flooding of the water tanker room.

2、Fixed part

Top cover, bottom ring, seat ring, support ring and so on.

1) Top cover

The main role: to form the flow channel and withstand the corresponding fluid pressure; fixed and support the activities of the guide vane and its connecting rod mechanism; support the water guide bearing; support and composition of the unit's seals, including the main shaft seal, maintenance seals, on the labyrinth ring, and so on.

2)Bottom ring

Role: Forming the overflow channel together with the top cover; installing the bearing under the guide vane.

3) Base ring (support ring)

Function: to put the seat ring when the unit is installed and become the foundation of the seat ring; to place the runner when the turbine is installed and overhauled.

4) Tail water pipe

The tail water pipe is located below the runner and is the main flow-through part, which is used to guide the water flow in and out of the runner.

When the water pump turbine is running as a hydraulic turbine, the section of the tail water pipe is required to be of slow diffusion type.

3、Buried part

Worm shell, seat ring, etc.

(C) Hydraulic turbine guide bearing

Role: one is to bear the radial force transmitted through the main shaft when the unit is running under various working conditions; the second is to maintain the adjusted axial position.

1、Circulation method of cartridge water guide bearing

Cartridge tile oil circulation is self-circulation, lubricant self-circulation principle: when the unit is running, installed in the large shaft of the water guide bearing rotating oil basin and the large shaft with the rotation, rotation of the oil basin in the oil followed by the rotation, due to the role of centrifugal force, the oil level in the oil basin to form the edge of the high, the center of the state of the low, that is, the formation of a paraboloid surface. Under the action of the pressure difference, the oil enters the lower annular oil groove of the tile surface through the oil inlet holes outside the circumference of the stationary bearing body, due to the rotation of the large shaft so that the oil moves upward along the slanting oil groove on the surface of the tiles and flows through the entire tile surface, so that the large shaft and the tiles of the lubrication between the good, while taking away the heat, the hot oil flows to the upper annular oil groove by the discharge pipe to the cooler, the hot oil is cooled by the inlet tube into the basin, the above lubricating oil The above lubricating oil path is a working process. When the unit is running, the lubricating oil is circulated in such a way to meet the running needs of the bearings.

2、Hydraulic turbine protection device

Hydraulic turbine protection device is to automatically take protection or interlocking measures to prevent accidents from occurring and expanding when faults endangering the safety of equipments and people occur in the process of starting, stopping and running of the unit, so as to ensure that the safety of people and equipments will not be damaged or the damages will be reduced to the minimum.

(1) Guide bearing temperature protection device

2) Guide bearing oil level protection device

Boland Renewable Energy Co.,LTD As an integrated new energy power company, providing youwith high quality integrated wind energy , solar energy and energy storage system solutions.Boland is now a subsidiary of CRRC, and is responsible for the overseas expansion of CRRC's wind power & solar power business. We have a relatively complete internal supply chain, service network and excellent product quality and technology.

Boland Provide power plant EPC,Power plant investment and acquisition.

Please feel free contact us if you need any technical support.Cheers for our cooperation!

My email:marketing@boland-hydroturbine.com

WA:+8613923745989