Wind power generation hydraulic pitch technology full analysis

1, wind power generation hydraulic pitch concept, composition, function

As one of the core parts of the control system of large wind turbine, the wind power pitch system adjusts the pitch angle of the paddle blades, adjusts the angle between the blades and the wind direction automatically according to the size of the wind speed, and then controls the aerodynamic torque and aerodynamic power captured by the wind turbine, in order to optimize the efficiency of the wind energy captured and the operational performance of the generator set. The pitch system is to realize the rotation of the paddle blades and change the pitch angle to ensure the power balance of the WTG above the rated wind speed. In extreme cases, the pitch system will automatically complete the closing action to reduce the resistance of the blades to the wind, so as to reduce the rotational speed and load of the WTG. This can effectively prevent WTGs from being damaged under extreme conditions and protect the safety of WTGs. The pitch system plays a very important role in the safe, stable and efficient operation of the turbine.

Wind pitch system can be divided into hydraulic pitch system and electric pitch system, hydraulic pitch system with motor-driven hydraulic pump as the working power, hydraulic oil as the transmission medium, solenoid valve as the control element, through the cylinder piston rod movement into the paddle blade circular motion to realize the pitch.

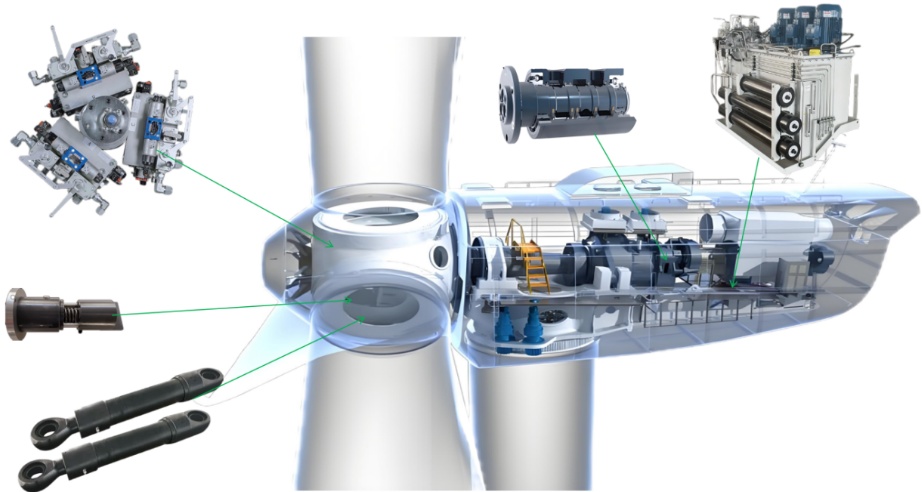

In the hydraulic pitch system, hydraulic pump station, hydraulic slip ring, pitch valve group, proportional valve, accumulator and cylinder are important components to ensure the normal operation of the system.

The hydraulic pump station provides stable hydraulic power for the whole hydraulic system and is the power source of the system. The hydraulic slip ring is used to connect the hydraulic pump station inside the nacelle with the rotating blade section, ensuring that the high-pressure oil can be smoothly transferred to the pitch manifold and cylinder. According to the instruction from the control system, the pitch valve unit precisely controls the expansion and contraction of the cylinder to realize the angle adjustment of the blade. The accumulator plays various roles in the hydraulic pitch system, including serving as an auxiliary power source, maintaining the system at constant pressure, providing an emergency power source, absorbing hydraulic shocks and so on. In an emergency, such as a sudden loss of system pressure or power failure, the accumulator can quickly release the stored hydraulic fluid to ensure that the paddle can be safely retracted to the predetermined position. The oil cylinder is the actuator, which realizes the angle adjustment of the paddle according to the instruction of the control system and the adjustment of the pitch valve group.

2, wind power generation hydraulic pitch performance advantages and value advantages

With the continuous development of wind power generation technology, the hydraulic pitch system, as an important part of the wind turbine, gradually highlights its performance and value advantages. In the following, the hydraulic pitch system is analyzed in depth from two perspectives: performance and value.

01. Performance advantages of hydraulic pitch for wind power generation

High reliability and low failure rate

Hydraulic pitch system adopts mature and stable hydraulic technology, which has high reliability and low failure rate. This means that wind turbines can maintain stable operation for a long period of time during operation, reducing downtime due to malfunctions and improving power generation efficiency.

Fast response and precise adjustment

The hydraulic pitch system has a fast response speed and high adjustment accuracy. When the wind speed changes, the hydraulic pitch system can quickly adjust the angle of the turbine blades to adapt to different wind conditions, thus ensuring the efficient operation of the wind turbine.

High torque output

The hydraulic pitch system provides a high torque output, which enables the wind turbine to maintain stable operation in complex wind conditions. The high torque output also increases the adaptability and reliability of the wind turbine.

Damping and Cushioning

The presence of hydraulic damping can absorb the impact torque above the blade rotor shaft, providing a good shock absorption and cushioning effect on the blades and the wind turbine itself.

Simplified maintenance, eliminating the need for tooth lubrication

Hydraulic pitch systems use simpler bearings, eliminating the need to lubricate gears and reducing the number of lubrication points for centralized lubrication. In conventional gear systems, tooth lubrication is essential to minimize friction and wear between gears. However, hydraulic pitch systems eliminate the need for tooth lubrication by using hydraulic fluid to transmit force. This not only simplifies maintenance procedures, but also reduces potential problems caused by inadequate or excessive lubrication.

Gearless transmission solves gear wear problems

No gears, fast backlash-free frequency response and no gear wear: Gear transmissions gradually fail due to friction and wear over long periods of operation, requiring regular replacement and maintenance. In contrast, the hydraulic pitch system directly drives the paddles by means of hydraulic cylinders, eliminating the need for gears and therefore eliminating the problem of gear wear. This greatly reduces the maintenance cost and failure rate of the system, and improves the reliability and service life of the system.

Emergency paddle shunts for long life and fast response time

The use of accumulators as emergency pitch power allows for emergency pitch shunting in the event of a complete power failure. Long service life and quick response in emergency.

02. Value Benefits of Hydraulic Pitch for Wind Turbines

Increased power generation efficiency

The hydraulic pitch system enables wind turbines to better capture wind energy and convert it into electricity by quickly responding and precisely adjusting the angle of the turbine blades. This helps to increase the efficiency of wind turbine power generation and reduce power generation costs.

Reduced O&M costs

The high reliability and low failure rate of the hydraulic pitch system reduces the operation and maintenance costs of the wind turbine. At the same time, the ease of maintenance and overhaul of the hydraulic pitch system further reduces O&M costs and increases equipment availability. In gear-driven systems, when the gears wear out to a certain extent, lifting operations may be required to replace or repair the gears. This not only increases the complexity and cost of maintenance, but may also affect the normal operation of the wind turbine. Hydraulic pitch systems, on the other hand, do not require gearing and therefore do not need to be lifted, reducing maintenance difficulties and costs.

Improved safety

The hydraulic pitch system utilizes an accumulator for emergency pitch change, which can quickly support full pitch operation of the hydraulic pitch cylinder in case of emergency, thus improving the safety of the wind turbine. In addition, the stability and reliability of the hydraulic pitch system helps to minimize safety accidents caused by malfunctions.

Stable and reliable, resistant to lightning interference, reducing the risk of downtime

Since the hydraulic pitch system mainly relies on hydraulic oil to transmit power instead of complex electrical lines and electrical components, it is not susceptible to the direct effects of lightning, electromagnetic interference, etc. Even under severe lightning weather conditions, the hydraulic pitch system can maintain better stability and reliability, reducing downtime.

شركة بولاند للطاقة المتجددة المحدودة، شركة متكاملة للطاقة الجديدة، تُقدم لكم حلولاً متكاملة عالية الجودة لطاقة الرياح والطاقة الشمسية وأنظمة تخزين الطاقة. بولاند الآن شركة تابعة لشركة CRRC، وهي مسؤولة عن التوسع الخارجي لأعمال CRRC في مجال طاقة الرياح والطاقة الشمسية. نمتلك سلسلة توريد داخلية متكاملة نسبيًا، وشبكة خدمات، وجودة منتجات وتقنيات ممتازة.

بولاند توفر محطة توليد الكهرباء EPC والاستثمار والاستحواذ في محطة توليد الكهرباء.

لا تتردد في الاتصال بنا إذا كنت بحاجة إلى أي دعم فني.

بريدي الإلكتروني: marketing@boland-hydroturbine.com

واشنطن: +8613923745989